INDUSTRIJSKI MATERIALI ZA 3D TISKANJE

Inženirski materiali vam omogočajo, da s 3D tiskanjem izdelate dele, primerne za vsako fazo proizvodnega procesa.

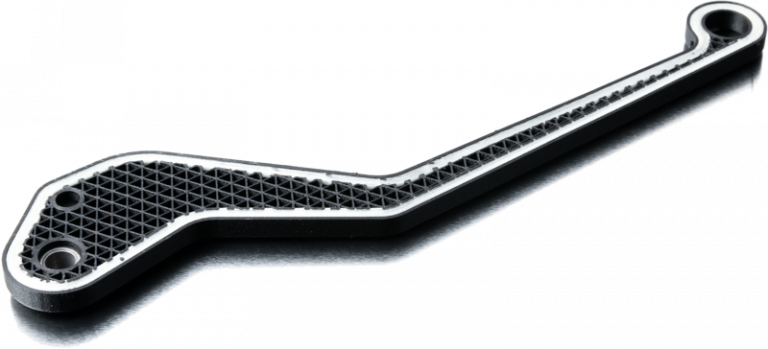

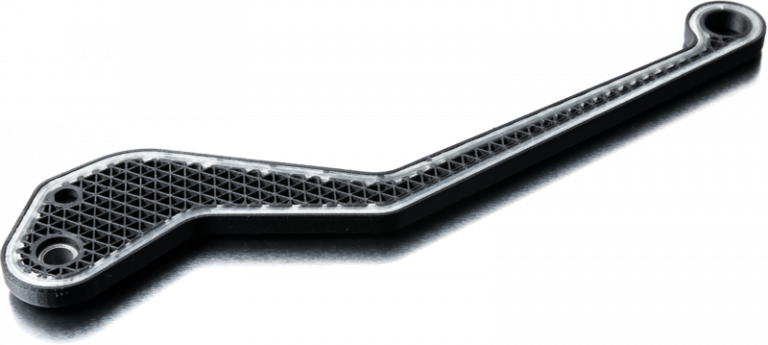

ONYX

Že 40% trši od ABS-a, Onyx predstavlja podlago za Markforged-ove 3D tiskane napredne kompozitne materiale. Tiskamo ga lahko samostojno ali ga dodatno ojačimo s katerim koli od štirih ojačitvenih vlaken.

VLAKNENI MATERIALI

Markforged je prvo podjetje, ki ponuja 3D tiskana neprekinjena vlakna za izdelavo kompozitnih delov, ki so dovolj robustni, da lahko nadomestijo obdelane kovine.

Continuous Filament Fabrication (CFF) je metoda, s katero se ojačeni kompozitni kosi 3D tiskajo. Neprekinjena vlakna se brizgajo po plasteh podobno kot pri FFF.

Precise PLA

Precise PLA je cenovno ugodna termoplastika na osnovi PLA (polilaktična kislina iz naravnih materialov). PLA je zelo priljubljen material v svetu 3D tiska zaradi ugodnosti, enostavnosti tiska ter širokega spektra barv.

Smooth TPU 95A

Smooth TPU (termoplastični poliuretan) je gumi podoben material, ki se uporablja v delih, kjer je potrebna prožnost, stisljivost in absorpcija udarcev.

Knjižnica materialov

Termoplastični gradbeni materiali

Onyx

Močan, tog material s toplotno odpornostjo in visoko dimenzijsko stabilnostjo.

Tip materiala: PA6 + mikro karbonski delci

Natezna trdnost: 40 MPa

Raztezek pri lomu: 25 %

Toplotna odpornost: 145 °C

Kompatibilno z: Desktop serija, Industrial serija

Onyx FR

Nevnetljiv Onyx, ki ustreza specifikacijam UL94 V-0 do 3 mm, deli kemijske in fizikalne lastnosti

Tip materiala: PA6 + mikro karbonski delci

Natezna trdnost: 41 MPa

Raztezek pri lomu: 18 %

Toplotna odpornost: 145 °C

Kompatibilno z: Industrial serija

Onyx ESD

Močnejša, trdnejša in ESD varna različica Onyx za industrijsko uporabo.

Tip materiala: PA6 + mikro karbonski delci

Natezna trdnost: 52 MPa

Raztezek pri lomu: 25 %

Toplotna odpornost: 138 °C

Površinska upornost: 105 – 107 Ω

Kompatibilno z: Industrial serija

Nylon White

Trden material z gladko površinsko teksturo za ponavljajoč se stik s kožo ali prijemala pri delih z visoko poliranih površin.

Tip materiala: PA6

Natezna trdnost: 51 MPa

Raztezek pri lomu: 150 %

Toplotna odpornost: 41 °C

Kompatibilno z: Mark Two, X7

Precise PLA

Cenovno dostopni material za tisk preciznih prototipov in validacijo.

Ni možnosti ojačitve z vlakni.

Tip materiala: PLA

Natezna trdnost: 31 MPa

Raztezek pri lomu: 27 %

Toplotna odpornost: 52 °C

Kompatibilno z: Onyx Pro, Mark Two, Industrial series

Smooth TPU 95A

Smooth TPU (termoplastični poliuretan) je gumi podoben material, ki se uporablja v delih, kjer je potrebna prožnost, stisljivost in absorpcija udarcev.

Tip materiala: S-TPU

Trdota po Shore A: 95

Prožnostni modul pri 2% deformaciji (MPa): 98

Prožnostni modul pri 100% deformaciji (MPa): 13

Natezna deformacija pri porušitvi (%): 550

Upogibni modul (MPa): 90

Kompatibilno z: Onyx Pro, Mark Two, Industrial series

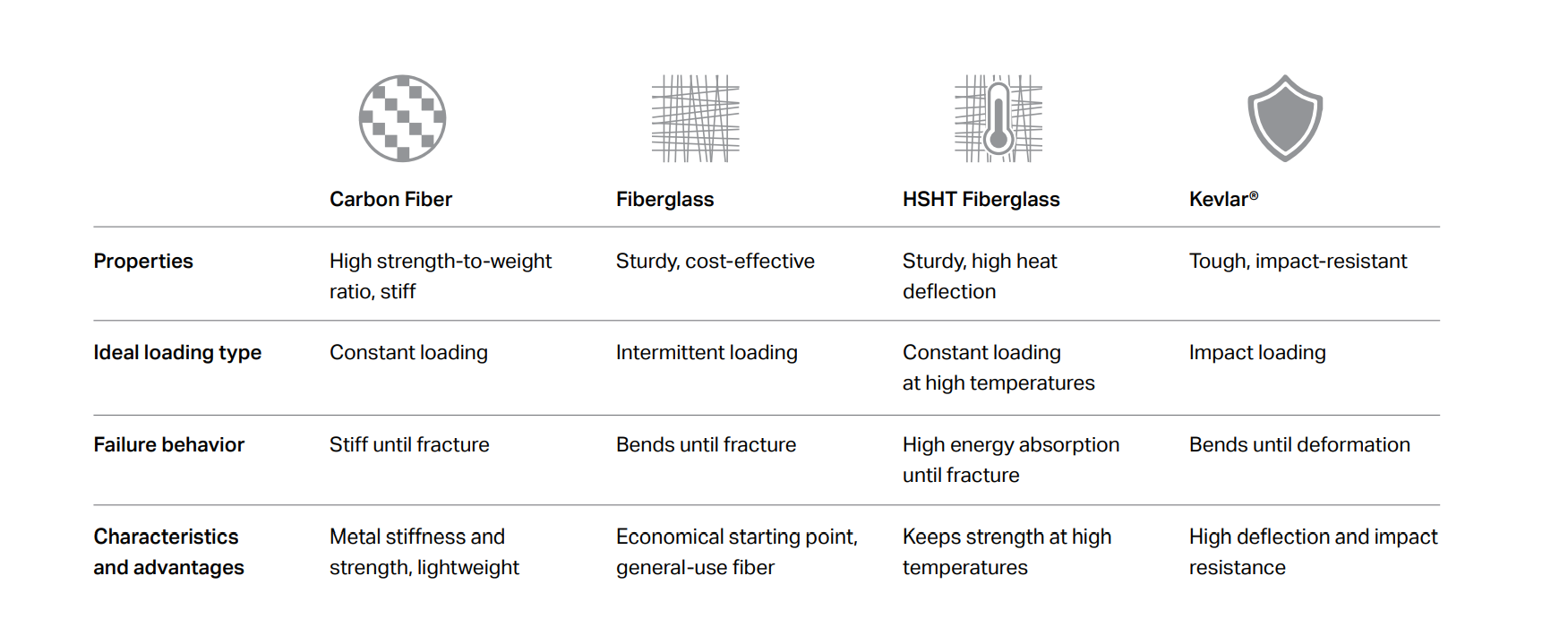

Ojačitvena vlakna

Fiberglass

Steklena vlakna Fiberglass so stroškovno najučinkovitejši material. So močna kot karbonska vlakna, vendar so 40% trdnejša in dvakrat težja. Primerno za vsakodnevne aplikacije, kjer potrebujete močne dele.

Natezna trdnost: 590 MPa

Raztezek pri lomu: 3,8%

Upogibna trdnost: 200 MPa

Toplotna odpornost: 105 °C

Kompatibilno z: Onyx Pro, Mark Two, X5, X7

HSHT Fiberglass

Visoko trdna in visokotemperaturna steklena vlakna (HSHT) so material, ki je edinstveno zasnovan za uporabnike, ki potrebujejo močne dele v okoljih z višjimi temperaturami (nad 105 ° C, s toplotno odporno točko 150 ° C).

Natezna trdnost: 600 MPa

Raztezek pri lomu: 3,6%

Upogibna trdnost: 420 MPa

Toplotna odpornost: 150 °C

Kompatibilno z: Mark Two, X7

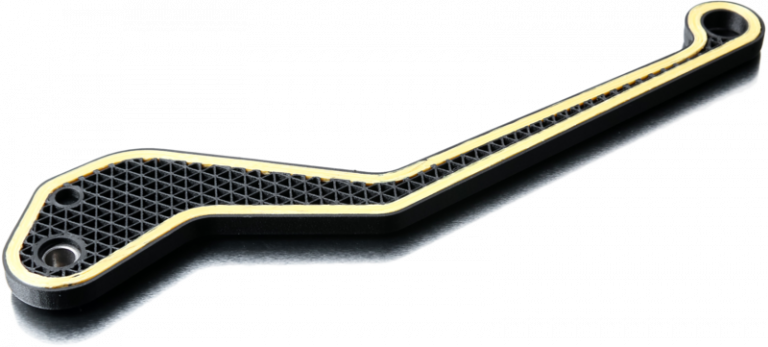

Carbon fiber

Karbonska vlakna imajo najvišjo razmerje med maso in trdnost ter tudi najvišjo toplotno prevodnost. Kot nalašč za aplikacije, ki zahtevajo največjo možno togost in trdnost.

Natezna trdnost: 800 MPa

Raztezek pri lomu: 1,5%

Upogibna trdnost: 540 MPa

Toplotna odpornost: 105 °C

Kompatibilno z: Mark Two, X7

Kevlar

Kevlar ima najboljšo odpornost proti obrabi in je naš najbolj prilagodljiv material. Namenjen za dele, ki so trpežni in odporni na udarce.

Natezna trdnost: 610 MPa

Raztezek pri lomu: 2,7%

Upogibna trdnost: 240 MPa

Toplotna odpornost: 105 °C

Kompatibilno z: Mark Two, X7

Carbon fiber FR

Carbon Fiber FR is a flame-retardant variant of Markforged’s

unique, ultra-high-strength Continuous Carbon Fiber — when used

to reinforce a Composite Base material like Onyx FR, it can yield

parts as strong as 6061-T6 Aluminum.

Natezna trdnost: 760 MPa

Natezna deformacija pri porušitvi: 1,6%

Upogibna trdnost: 540 MPa

Toplotna odpornost: 105 °C

Kompatibilno z: X7