INDUSTRIAL 3D PRINTING MATERIALS

Engineering-grade materials enable you to use 3D printing to make parts suitable for every stage in the manufacturing process.

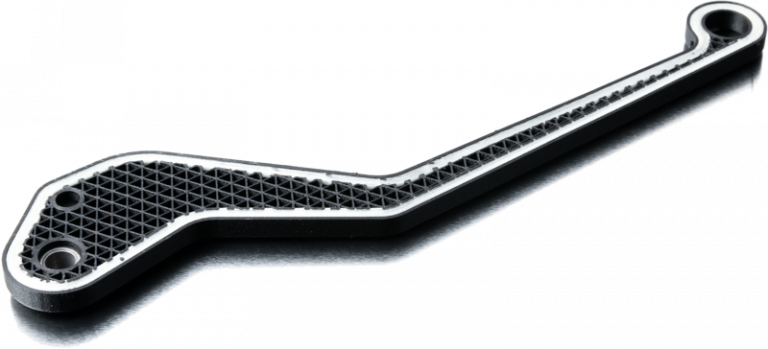

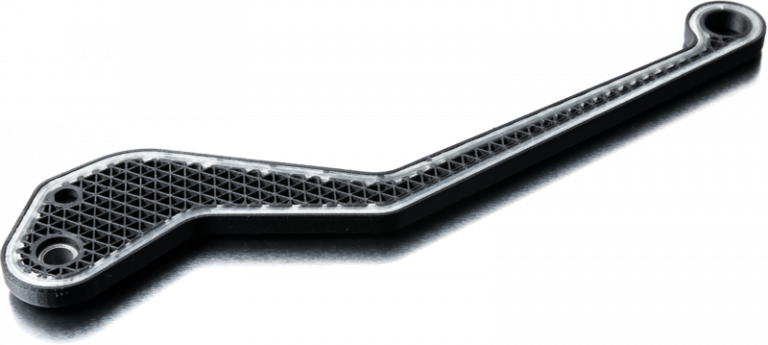

ONYX

Already 40% stiffer than ABS, Onyx provides the foundation for Markforged’s 3D printed advanced composites materials. It can be printed on its own or reinforced with any of our four continuous fibers.

FIBER MATERIALS

Markforged is the first company to offer 3D printed continuous fibers, enabling composite parts robust enough to replace machined metal.

Continuous Filament Fabrication (CFF) is the method with which fiber reinforced composites are 3D printed. Continuous fibers are extruded layer-by-layer similarly to FFF processes.

Precise PLA

Precise PLA is Markforged easy-to-print plastic for precision concept modeling and validation. Based on the most common 3D printing prototyping material, Precise PLA 3D prints without warping and comes in a variety of colors. Best of all, it’s affordable. So you can use as much as you need to fine-tune your designs before implementation.

Smooth TPU 95A

Smooth TPU 95A is a rubber-like material that when used with Markforged composite printers offers product developers and manufacturers the ability to create flexible, impact-absorbent parts on demand.

Material library

Thermoplastic build materials

Onyx

Strong, stiff material with heat resistance and high dimensional stability.

Material type: PA6 + choped carbon fiber

Tensile strength: 40 MPa

Elongation at break: 25 %

Heat deflection: 145 °C

Compatible with: Desktop series, Industrial series

Onyx FR

Flame retardant, meets UL94 V-0 specification down to 3 mm, shares the chemical and physical attributes of Onyx.

Material type: PA6 + chopped carbon fiber

Tensile strength: 41 MPa

Elongation at break: 18 %

Heat deflection: 145 °C

Compatible with: Industrial series

Onyx ESD

Stronger, stiffer, and ESD resistant Onyx variant for industrial applications.

Material type: PA6 + chopped carbon fiber

Tensile strength: 52 MPa

Elongation at break: 25 %

Heat deflection: 138 °C

Surface Resistance: 105 – 107 Ω

Compatible with: Industrial series

Nylon White

Tough material with smooth surface texture for repeated skin contact or work holding when handling highly polished surfaces.

Material type: PA6

Tensile strength: 51 MPa

Elongation at break: 150 %

Heat deflection: 41 °C

Compatible with: Mark Two, X7

Precise PLA

Affordable to-print plastic for precision concept modeling and validation.

Cannot be reinforced with fiber.

Material type: PLA

Tensile strength: 31 MPa

Elongation at break: 27 %

Heat deflection: 52 °C

Compatible with: Onyx Pro, Mark Two, Industrial series

Smooth TPU 95A

Rubber-like material that when used with Markforged composite printers offers product developers and manufacturers the ability to create flexible, impact-absorbent parts on demand.

Material type: S-TPU

Shore Hardness (Shore A): 95

Tensile Modulus at 2% strain (MPa): 98

Tensile Modulus at 100% strain (MPa): 13

Tensile Strain at break (%): 550

Flexural Modulus (MPa): 90

Compatible with: Onyx Pro, Mark Two, Industrial series

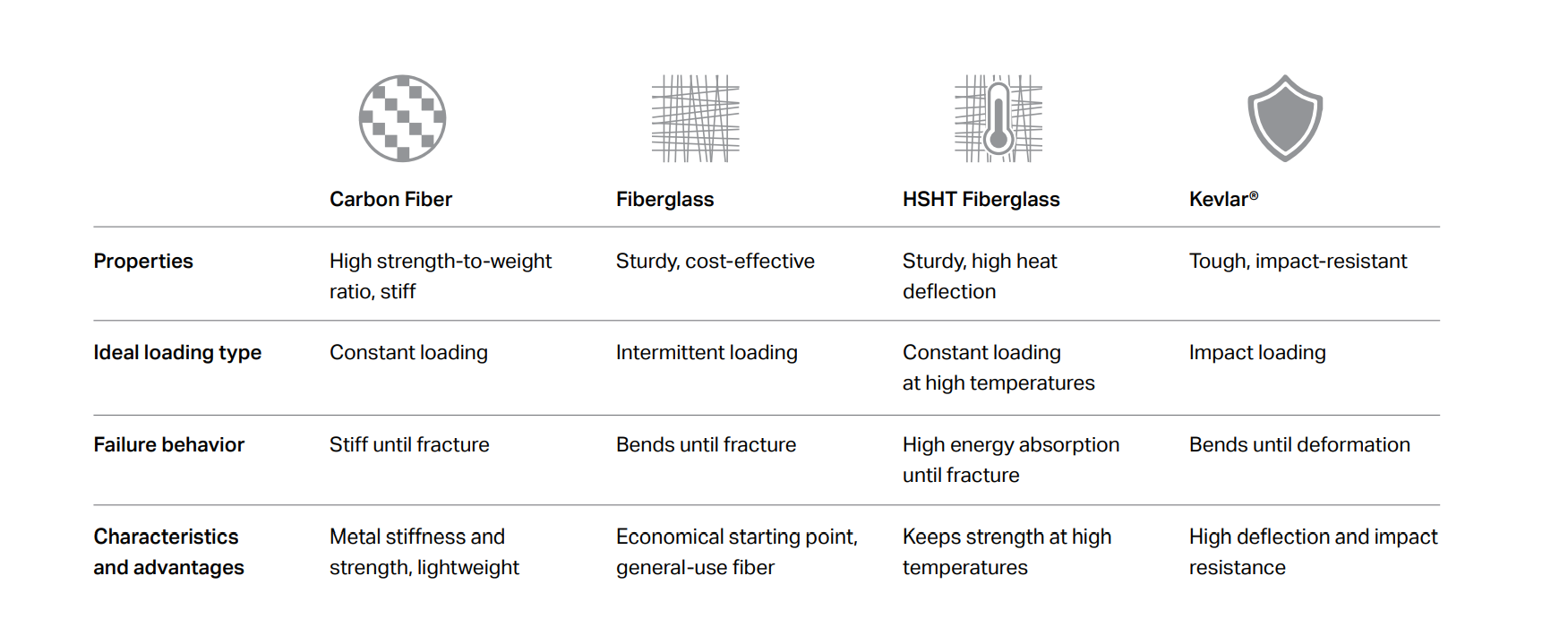

Fiber reinforcement materials

Fiberglass

Fiberglass is the most cost-effective material. It’s a strong as Carbon Fiber, but 40% as stiff, and 2X the weight. Suited to everyday applications where you need strong parts.

Tensile strength: 590 MPa

Elongation at break: 3,8%

Flexural strength: 200 MPa

Heat deflection: 105 °C

Compatible with: Onyx Pro, Mark Two, X5, X7

HSHT Fiberglass

High Strength, High Temperature (HSHT) Fiberglass is a material uniquely designed for users who need strong parts in higher temperature environments (over 105°C, with a heat deflection point of 150°C).

Tensile strength: 600 MPa

Elongation at break: 3,6%

Flexural strength: 420 MPa

Heat deflection: 150 °C

Compatible with: Mark Two, X7

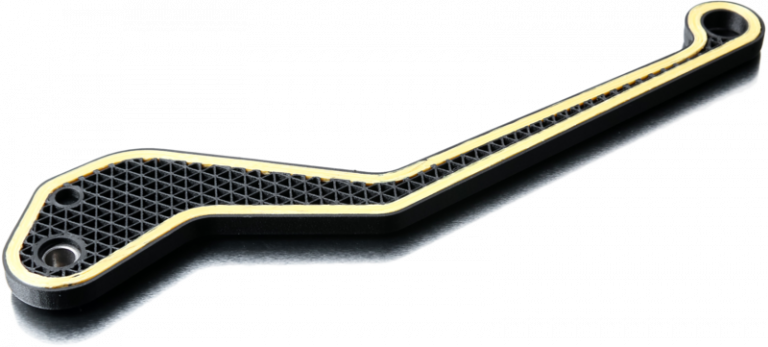

Carbon fiber

Carbon fiber has the highest strength to weight as well as the highest thermal conductivity. Perfect for applications requiring the greatest possible stiffness and strength.

Tensile strength: 800 MPa

Elongation at break: 1,5%

Flexural strength: 540 MPa

Heat deflection: 105 °C

Compatible with: Mark Two, X7

Kevlar

Kevlar has the best abrasion resistance and is our most flexible material. For when you need parts that are durable and resistant to impact.

Tensile strength: 610 MPa

Elongation at break: 2,7%

Flexural strength: 240 MPa

Heat deflection: 105 °C

Compatible with: Mark Two, X7

Carbon fiber FR

Carbon Fiber FR is a flame-retardant variant of Markforged’s

unique, ultra-high-strength Continuous Carbon Fiber — when used

to reinforce a Composite Base material like Onyx FR, it can yield

parts as strong as 6061-T6 Aluminum.

Tensile strength: 760 MPa

Tensile strain at break: 1,6%

Flexural strength: 540 MPa

Heat deflection: 105 °C

Compatible with: X7